CS533E

Product Description

CS533E – UTE CAT COMPACTORS

The CS533E Soil Compactors offer high compaction performance, speed and gradeability to maximize productivity while providing exceptional reliability and durability.

- SPECIFICATIONS

- BENEFITS AND FEATURES

SPECIFICATIONS

Weights

| Operating Weight with Cab | 10840.0 kg |

| Operating Weight with ROPS/FOPS | 10485.0 kg |

| Weight at Drum with Cab | 5760.0 kg |

| Weight at Drum with ROPS/FOPS | 5570.0 kg |

Operating Specifications

| Compaction Width | 2134.0 mm |

| Ground Clearance | 543.0 mm |

| Static Linear Load, with Cab | 27.0 kg/cm |

| Static Linear Load, with ROPS/FOPS | 26.1 kg/cm |

| Travel Speed – Maximum | 12.0 km/h |

| Turning Radius Inside Drum Edge | 3.68 m |

Engine

| Gross Power | 97.0 kW |

| Engine Model | Cat 3054C |

Dimensions

| Drum Diameter | 1534.0 mm |

| Drum Width | 2134.0 mm |

| Height with ROPS/FOPS or Cab | 3.07 m |

| Overall Length | 5.51 m |

| Overall Width | 2.29 m |

| Wheelbase | 2.9 m |

Vibratory System

| Centrifugal Force – Maximum | 234.0 kN |

| Centrifugal Force – Minimum | 133.0 kN |

| Nominal Amplitude – High | 1.8 mm |

| Nominal Amplitude – Low | 0.85 mm |

| Vibratory Frequency – Standard | 31/34 Hz (1,860/2,040 vpm) |

Tires

| Tires | 23.1 × 26 8-ply flotation |

Service Refill Capacities

| Fuel Tank Capacity | 200.0 L |

BENEFITS AND FEATURES

Engine

Cat® 3054C turbocharged electronic diesel delivers 97 kW (130 hp) and is built for performance and reliability without sacrificing fuel economy.

Turbocharged Air-to-air Aftercooling

The turbocharged air-to-air aftercooling provides improved fuel economy by packing cooler, denser air into cylinders for more complete combustion of the fuel and lower emissions.

Direct-Injection of Fuel

The direct-injection of fuel provides maximum efficiency.

Cross-flow Cylinder Head

The cross-flow cylinder head improves air flow into cylinder which increases power while lowering fuel consumption, engine emissions and noise.

Oil Pump

A low-mounted oil pump allows for quick start-up-lubrication.

Large Oil Cooler

A large oil cooler reduces oil deterioration and varnishing of internal components. Allows for 500 hour engine oil change intervals.

Meets Emission Control Standards

The engine meets U.S. EPA Tier 2 and European EU Stage II emissions control standards worldwide.

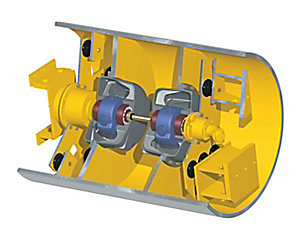

Vibratory System

The pod-style vibratory system delivers superior compactive force while offering serviceability advantages.

Pod-style Weight Housings

The pod-style weight housings are assembled and sealed at the factory to ensure cleanliness, longer bearing life and easier field exchange or service.

Dual Amplitude

Dual amplitude works efficiently in a wider range of applications. High or low amplitude is selected from the operator’s station.

Heavy-duty Bearings

Large heavy-duty bearings for the eccentric weight shaft are designed for high compactive forces.

Vibratory Bearing Lube Service

3 year/3000 hour vibratory bearing lube service interval reduces maintenance.

Isolation Mounts

Heavy-duty isolation mounts allow more force to be transmitted to the ground and less vibration to the drum yoke.

Proprietary Eccentric Weights

The proprietary eccentric weights on the CS533E provide reliable dual amplitude selection and the innovative design ensures precise performance.

Positive Amplitude Selection

The positive amplitude selection is accomplished when the steel shot is repositioned inside the hollow eccentric weight. Direction of the weight shaft rotation determines amplitude level.

Simplified Control

There is simplified control from the operator’s station with a selection switch on the operator’s console.

High Reliability

The weights are highly reliable since there is no chance of the high-strength spherical steel shot wedging together. System reliability is superior to swinging mechanical weights and is also quieter during starts and stops.

Long Service Life

The proprietary eccentric weights have a longer service life because there are no heavy weights to slam together and no metal fragments to contaminate the bearing lubrication system.

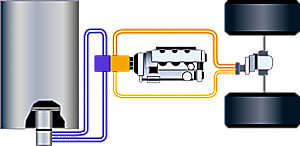

Dual Pump Propel System

The dual pump propel system provides high tractive effort and gradeability for outstanding productivity in tough applications.

Propel Pumps

The dual propel pumps provide separate, balanced hydraulic flow to the rear wheel axle and the drum drive motors. Ample power is provided for compacting on moderate slopes and increases tractive effort in loose or poor underfoot conditions.

Limited Slip Differential

Limited slip differential provides balanced tractive effort and smooth torque transfer to both rear wheels.

Two Speed Ranges

There are two speed ranges for versatile operation. Low speed range for vibratory operation and maximum torque when climbing grades. High speed range moves the machine quickly over longer distances.

Flushing Valves

The flushing valves in each propel circuit help keep hydraulic oil cool and clean for maximum system efficiency.

Operator’s Station

The operator’s station is ergonomically designed for maximum operator productivity while offering excellent visibility and unmatched comfort.

Single Lever Control

A single lever control for propel and vibratory On/Off provides simple and low effort operation. A padded adjustable wrist rest provides comfort.

Comfortable and Durable Seat

A comfortable and durable seat has adjustable fore/aft position, bottom cushion height, suspension stiffness and flip-up arm rests with a 76 mm (3″) wide retractable seat belt.

Operator’s Station

Isolated operator’s station with four heavy-duty rubber mounts limits machine vibration transmitted to the operator’s station.

Rubber Floor Mat

A rubber floor mat provides sure footing and helps further isolate the operator from machine vibration and noise.

Gradeability and Machine Control

The exclusive dual pump propel system provides superior performance, machine control and good grade climbing capability.

Two Propel Pump System

The two propel pump system has dedicated pumps to drive the heavy-duty, high-torque rear wheel and the drum motors independently. Should the drum or wheels begin to spin, the non-spinning motor still receives hydraulic flow, allowing continuous tractive effort especially useful in loose underfoot conditions.

Controllability

Controllability is another feature of the dual propel pumps. The operator is able to stop, maintain machine position and change directions while on grade.

Gradeability

The good gradeability of the CS533E allows high productivity. It is designed for typical applications working on level to moderate grades.

Visibility

The sloped fiberglass hood design provides good service access and exceptional operator visibility.

Visibility

Visibility to the tire edges and rear of the machine is exceptional. The sloped hood allows the operator to see obstacles measuring 1 meter (3’3″) high located 1 meter (3’3″) to the rear of the machine. Excellent visibility increases productivity when working near obstructions or maneuvering around the job site.

Visibility Lockable Engine Hood

The lockable engine hood opens quickly and easily with the use of gas struts to provide good access to the engine, cooling system and all service points.

Low Sound Levels

Low sound levels for the operator and the ground crew is due to the engine hood and cooling air flow through the rear mounted radiator.

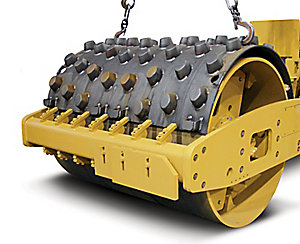

Padfoot Shell Kit

The optional padfoot shell kit makes the CS533E an extremely adaptable machine when compacting cohesive or semi-cohesive materials.

Open Platform with ROPS/FOPS Canopy

The platform on the CS533E is equipped with a ROPS/FOPS canopy and is enclosed by handrails and features angled foot rests for sure footing and support when working on a grade.

Working Environment

The platform has a spacious and comfortable working environment with all controls, levers, switches and gauges positioned to maximize productivity.

Visibility

There is unrestricted visibility to the drum and tire edge and to the side and rear of the machine.

Handrails

The platform is enclosed by handrails and features angled foot rests for sure footing and support when working on a grade.

Serviceability

The CS533E Soil Compactor provides the exceptional reliability and serviceability that you’ve come to expect from Caterpillar.

Visual Indicators

Visual indicators allow easy check of the engine coolant, hydraulic oil tank level and air filter restriction.

Operator’s Station Tilts Forward

The operator’s station tilts forward to allow convenient access to the hydraulic pumps.

Rear Mounted Cooling System

A rear mounted cooling system provides easy access for cleaning. Hydraulic oil cooler tilts rearward for additional access to the radiator.

Sealed-for-life Bearings

Sealed-for-life bearings in the articulation hitch eliminate the need for greasing or maintenance.

500 Hour Engine Oil Change Interval

500 hour engine oil change interval.

Vibratory Bearing Lube Service

3 year/3000 hour vibratory bearing lube service interval for reduced maintenance.

Ecology Drains

Ecology drains provide an environmental method to drain fluids. They are included on the radiator, engine oil pan, hydraulic and fuel tanks.

Secure Hose Routing

Secure hose routing with polyethylene mounting blocks reduce rubbing and increase service life.

Electrical System Integrity

Nylon braided-wrap and all-weather connectors ensure electrical system integrity. Electrical wiring is color-coded, numbered and labeled with component identifiers to simplify troubleshooting.

Product Link Wire-ready

The Cat Product Link System (PLS) ensures maximum uptime and minimum repair costs by simplifying tracking of equipment fleets. The system provides automatic machine location and hour updates. The Cat Product Link System can be obtained through your local Cat dealer.

Selection of right Construction Equipment for your Project